Apple has offered a rare glimpse into the extensive durability testing its iPhones undergo before they hit the market. Tech reviewer Marques Brownlee, aka MKBHD, shared details on X, revealing the various stages of water resistance testing and the use of specialized robots for drop tests.

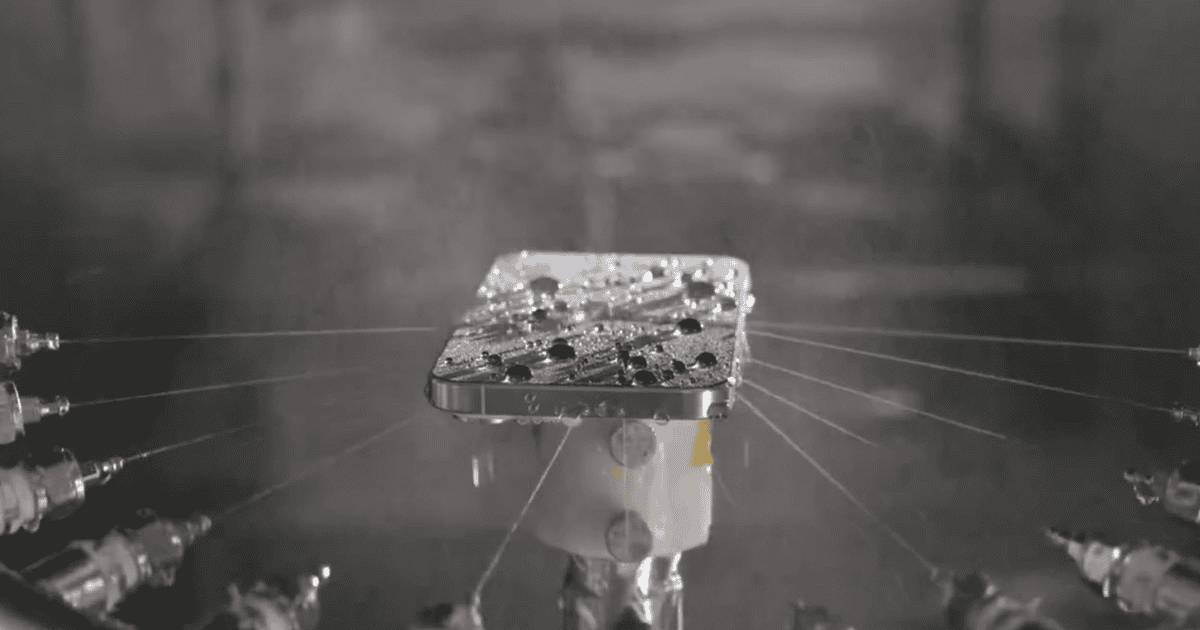

According to Brownlee, Apple has a dedicated room with machines specifically designed for water and dust ingress testing.

iPhones go through four progressive levels,

- simulating rain showers,

- low-pressure jets,

- high-pressure blasts, and finally,

- submersion with added pressure to mimic depth.

These tests ensure iPhones achieve the desired IP ratings, with the latest models reaching IP68 for water and dust resistance.

There’s more than this. Apple reportedly uses an industrial robot programmed to perform drop tests from hundreds of different angles and onto various surfaces. High-speed cameras capture the impact in slow motion, from which engineers analyze the phone’s behavior. This comes after Apple stopped manufacturing fine woven cases because of poor durability.

Durability testing also involves simulating real-world vibrations. Apple can program machines to shake the iPhone at specific frequencies, copying the vibrations of a motorcycle engine or a subway car. This helps assess how the phone holds up to extended exposure to such vibrations.

But all of this comes with a cost. Tight seals and adhesives necessary for waterproofing make it more challenging to repair the phone. However, the head of hardware engineering, John Ternus, argues that the improved reliability outweighs the repairability concerns, especially considering the environmental impact of replacing devices that frequently fail.

Apple reportedly tests over 10,000 iPhones before launch.